Ever wondered how the stuff you use every day your phone, your car, even your toothpaste gets made so flawlessly? That’s where process technology steps in. It’s the unsung hero behind the scenes, turning raw materials into finished products with precision and efficiency.

Whether you are new to the term or curious about how it shapes our world, this guide breaks it all down for you. From powering industries to launching careers, we’ll explore every angle of this fascinating field. Buckle up it is going to be a ride full of surprises!

What is Process Technology? A Complete Beginner’s Guide

Imagine you are brewing your morning coffee. You grind the beans, heat the water just right, and time the pour. Now scale that up a thousand times, add some science, and swap your kitchen for a factory that’s process technology in a nutshell. It’s the art and science of transforming raw stuff like oil, metal, or chemicals into things we use every day.

At its core, process technology blends engineering systems with practical know-how. It’s about designing, running, and tweaking production processes to make them faster, safer, and smarter. Think of it as the recipe and the chef for modern industry. From the oil production industry churning out gasoline to food plants whipping up your favorite snacks, this field touches almost everything.

Here’s a quick breakdown:

- What it does: Turns ideas into reality through manufacturing technology.

- Where it lives: Everywhere—think energy, pharmaceuticals, even aerospace.

- Why it’s cool: It’s like solving a giant puzzle with machines and brains.

By the end of this guide, you’ll see how process automation and industrial processes keep our world spinning. Ready to dig deeper? Let’s go!

Process Technology Explained: How It Powers Modern Industries

Picture a factory screeching to a halt no fuel, no medicine, no cars. Chaos, right? Process technology keeps that nightmare at bay. It’s the heartbeat of industries, making sure production techniques run like clockwork. Whether it’s the petroleum sector refining crude oil or a brewery perfecting your IPA, this field is all about efficiency.

Take the oil production industry, for instance. Crude oil doesn’t magically become gasoline. Process technicians use reactors and pumps to heat, separate, and purify it a dance of process control and instrumentation products. According to the Energy Information Administration, U.S. refineries processed 17.9 million barrels daily in 2024 none of that happens without slick engineering systems.

Manufacturing technology powers everything from solar panels to sneakers. It’s about balancing speed with safety like walking a tightrope while juggling. Over the years, it’s evolved from sweaty manual labor to sleek process automation, cutting waste and boosting output. Next time you flip a switch or fill your tank, thank this tech for keeping the lights on.

What Does a Process Technologist Do? Career, Skills, and Salary Insights

Ever met someone who’s part mechanic, part scientist, and all problem-solver? That’s a process technician. These folks are the wizards behind the curtain, keeping factory systems humming. Their job? Monitor equipment, tweak production processes, and dodge disasters—all in a day’s work.

A typical shift might look like this:

- Checking gauges on a reactor to ensure steady pressure.

- Adjusting valves to keep the flow smooth in an industrial process.

- Analyzing data to spot hiccups before they blow up.

You’ll need sharp skills to join the ranks of plant operators or technical engineers:

- Analytical thinking: Spot patterns like a detective.

- Tech skills: Master control instruments and software.

- Cool head: Stay calm when alarms blare.

The U.S. Bureau of Labor Statistics pegs median pay at $62,000 annually in 2024, with top equipment specialists in the oil and gas employment sector hitting $85,000+. Plus, you get to work hands-on with cutting-edge gear. Sound exciting? It’s a career where boredom isn’t on the menu.

The Role of Process Technology in Manufacturing and Production

Think of a factory as a giant Lego set. Process technology snaps every piece into place. It’s the glue in manufacturing flow, making sure raw materials morph into finished goods without a hitch. From assembly lines to chemical plants, it’s all about process optimization.

Take car manufacturing. A single sedan rolls off the line every 60 seconds at top plants like Toyota’s. That speed? It’s thanks to industrial operations syncing robots, conveyors, and workers. Production machinery hums, waste drops, and costs shrink—music to any manager’s ears.

Safety’s a big win too. In the fuel industry, precise control engineering prevents leaks or explosions. A 2023 case study from ExxonMobil showed a 15% efficiency boost after upgrading their automated systems—proof this tech delivers. Better processes mean cheaper goods and safer workplaces. Pretty neat, huh?

How Process Technology Shapes Everyday Products — From Concept to Creation

That shiny smartphone in your hand? Process technology brought it to life. It’s the wizard turning raw ideas into stuff you can touch. Every product has a journey, and this tech steers the ship from start to finish.

Here’s how it works:

- Step 1: Raw materials—like silicon for chips—get prepped.

- Step 2: Industrial equipment shapes them with heat, pressure, or chemicals.

- Step 3: Automated monitoring ensures every piece is perfect.

Giant machines melt pellets, mold them in seconds, and cool them just right—all thanks to process automation. Or potato chips system regulation fries them crisp without burning. Mess up the timing, and you’ve got a soggy snack disaster! The American Petroleum Institute even sets standards to keep fuel flowing smoothly from refinery to pump. It’s the hidden hand making your day-to-day tick.

Why Process Technology Matters: Real-World Applications You Didn’t Know About

Bet you didn’t know process technology keeps planes soaring and your tap water clean. It’s not just factory stuff—it’s everywhere, quietly shaping your world. Let’s peel back the curtain on some mind-blowing uses.

- Aviation: Jet fuel refining relies on crude oil extraction and tight process control.

- Water: Purification plants use industrial sensors to zap bacteria.

- Renewables: Solar panel production leans on engineering tools for precision.

In 2022, a Texas textile mill cut energy use by 20% after tweaking its industrial mechanics. Small change, big win. The stakes are high without this tech, supply chains would collapse like dominoes. The Energy Information Administration notes that energy production alone supports 10 million U.S. jobs. So yeah, it’s a big deal keeping life safe, green, and convenient.

Process Technology vs. Industrial Engineering: What’s the Difference?

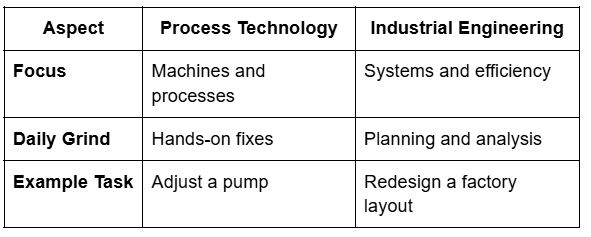

Process technology and industrial engineering walk into a bar who’s buying? They’re cousins, not twins, each with a unique vibe. Let’s break it down so you can pick your team.

Process technology is boots-on-the-ground. It’s about running the show think system controllers tweaking a reactor in the oil refining game. Industrial engineering, though? That’s the bird’s-eye view optimizing workflows and slashing inefficiencies across the board.

They overlap both love smooth operations—but one’s in the trenches, the other’s strategizing. A field operator might say, “I keep it running.” An engineer? “I make it run better.” Which sparks your interest?

Process Technology Careers: Is It the Right Path for You?

Ready to swap a cubicle for a buzzing control room? Process technology careers offer action, stability, and a chance to geek out on tech. From drilling jobs to plant supervisors, there’s a spot for every gearhead.

- Pay: Starts at $50K, climbs to $100K+ for pros in offshore employment.

- Demand: A workforce shortage means jobs galore 3% growth projected by 2030 (BLS).

- Variety: Run systems, lead teams, or troubleshoot calibration equipment.

Downsides? Shifts can be long, and pressure’s high think oilfield workforce handling live rigs. But if you thrive on puzzles and don’t mind a little grease, it’s gold. “It’s like being the heartbeat of the plant,” says Maria, a 10-year vet in energy jobs.

Key Components of Process Technology: Equipment, Systems, and Processes

Think of process technology as a rock band—every part jams together. Three key players make the magic: equipment, systems, and processes. Let’s meet the lineup.

- Equipment: The heavy hitters—pumps, reactors, and measurement tools. They do the grunt work.

- Systems: The brain—software and automation devices tying it all together.

- Processes: The rhythm—step-by-step moves from raw to ready.

Crude oil hits a distillation tower (equipment), sensors track the heat (systems), and a recipe splits it into gas and diesel (processes). Mess up one, and the whole tune’s off. The American Petroleum Institute sets the beat with strict guidelines. It’s a symphony of tech keeping industries rocking.

Future of Process Technology: Trends, Automation, and Innovations to Watch

Hold onto your hats, the future of process technology is speeding into sci-fi land! Process automation is already king, with robots and AI tackling the boring stuff. But what’s next? It’s wilder than you think.

- Green Tech: Carbon capture cuts emissions in the energy production game.

- Smart Factories: Industrial sensors and it makes plants think for themselves.

- 3D Printing: Custom parts on demand, thanks to production machinery.

Pingback: Deep Offshore Technology: Taming The Ocean’s Depths

Pingback: The Revolution Of Convincingly Authentic Media: How AI Is Transforming Digital Content Creation