In today’s ever-changing manufacturing environment, metal 3D printers are revolutionary devices changing the way that we design, prototype, and manufacture important components. These machines have moved beyond their initial prototyping use case to now being essential tools in production lines in many different industries.

This in-depth guide covers everything you need to know about metal 3D printing technology in 2025 including leading-edge machines and disruptive applications changing our world.

Revolutionizing Manufacturing: How Metal 3D Printers Are Shaping 2025 Industries

The manufacturing revolution made possible by metal 3D printers is not just coming it is here already. Unlike conventional manufacturing methods, which remove material to create parts, metal additive manufacturing adds layers together to build objects. This metal AM process opens the door to impossible designs in formerly fictitious reality.

A Cincinnati aerospace parts manufacturer recently cut production time by 60% after integrating Direct Metal Laser Sintering (DMLS) systems into their workflow. This dramatic improvement isn’t unusual. Across industries, metal 3D printing technology is slashing prototype development from months to mere days.

"We have completely reimagined our production process thanks to our metal 3D printer. Components that once required five separate parts now print as a single unit, with better performance and reliability." - Sarah Chen, Manufacturing Director at AeroTech Industries

Three key developments are driving this revolution:

- Material innovation – New specialized metal powders hit markets quarterly

- AI integration – Machine learning now monitors and adjusts print parameters in real-time

- Multi-material capabilities – Advanced systems can blend different metals within single builds

The statistics illustrate that the metal additive manufacturing market grew a remarkable 29% just last year, as the adoption of this technology is shifting from aerospace to heavy equipment manufacturing faster than any time before.

Top Metal 3D Printers of 2025: Cutting-Edge Technology for Precision Engineering

Each industrial 3D printer fills specific niches in the market. The EOS system excels in production reliability with its impressive 99.8% part consistency. GE’s machine handles reactive materials with exceptional precision, making it perfect for critical aerospace applications where failure isn’t an option.

For businesses seeking more accessible entry points, the Markforged system delivers impressive results at a fraction of laser-based systems’ cost. At the same time, the German engineering of TRUMPF is showcasing innovative functionality that eliminates support structures for many applications – a real time and material saver.

Why Metal 3D Printing Is the Future of Aerospace and Automotive in 2025

The aerospace large annual spenders and the automotive manufacturers have adopted metal 3D printing with gusto like never before – and rightly so.

Aerospace Applications

The latest fuel nozzles from Boeing are an exceptional example of the value of 3D printing for aerospace. What previously required 25 individual pieces now prints as a single part, providing:

- 31% weight reduction

- 19% increased fuel efficiency

- 5× longer component lifespan

SpaceX is further breaking the limits by regularly 3D printing SuperDraco thrust chambers in Inconel, offering thrust-to-weight ratios that aren’t possible with traditional manufacturing processes. The cooling channels follow optimal fluid dynamics paths that no CNC machine could ever make.

Automotive Breakthroughs

While Formula 1 teams pioneered metal 3D printing adoption in racing, mass-market applications have finally arrived. BMW’s i8 Roadster features printed aluminum components that:

- Cut parts count by 80%

- Reduce assembly time by 35%

- Maintain strength while significantly reducing weight

Three critical factors make metal 3D printing technology invaluable to these industries:

- Lightweighting without compromise – Every gram matters for performance and fuel consumption

- Supply chain simplification – Complex assemblies become single components

- Design freedom – Engineers now design for optimal performance, not manufacturing constraints

Metal 3D printers have matured beyond prototyping tools. They are now essential production equipment for mission-critical components where failure simply isn’t an option.

Unveiling 2025's Best Metal 3D Printers: Features, Costs, and Performance

Recognizing the total cost of a metal 3D printer extends much further than the price tag. Here is a complete overview of the metal 3D printing market in 2025:

Entry-Level Solutions ($100K-$250K)

The Markforged Metal X Gen 2 ($175,000) has a solid price point for any business that is considering metal additive manufacturing. It can print stainless steels, tool steels, as well as copper in a build volume of 300×220×200mm. It has an annual maintenance cost of approximately $15,000 making this option feasible for businesses small or big, as well as educational facilities.

The Desktop Metal Studio System 2 ($150,000) provides similar accessibility with its focus on 17-4PH, 316L, H13, and copper materials. With annual maintenance around $18,000, it’s perfect for engineering firms and research labs taking their first steps into metal 3D printing.

Mid-Range Production ($250K-$800K)

Going further up the scale, the 3D Systems DMP Flex 350 ($675,000) is able to print a wider variety of materials, including titanium and aluminum alloys. Featuring a build volume measuring 275×275×420mm, as well as exemplary performance, the Flex 350 is a strong contender for those manufacturers requiring medical devices or aerospace parts, but an annual maintenance cost of around $60,000 will require a thoughtful ROI process.

The Xact Metal XM300G ($420,000) offers a good compromise for job shops and mid-volume production having tool steels, stainless steels, and aluminum at a cost of $40,000 annually, while it does incur a relatively high annual maintenance cost it is a manageable part of an operating budget.

Industrial Production ($800K+)

At the high end, the EOS M 400-4 ($1.3 million) has enterprise capabilities with a robust metal material library, a large 400×400×400mm build volume, and a $120,000 annual maintanence cost, fully deserved given the extraordinary capabilities of its systems in high-volume, 3D printing environments.

The GE Additive X Line 2000R ($2.5 million) is the largest and certainly the highest priced, with an enormous 800×400×500mm build volume, it is by far the largest within the industrial 3D printers. For the respectable price of $200,000 per year to maintain, this is an investment suited for companies that produce large components or require serial manufacturing.

"The metal 3D printer ROI calculation must factor in reduced lead times, design optimization benefits, and consolidated multi-part assemblies. Our clients typically see 18-36 month payback periods when applications are properly selected." - Michael Rodriguez, Additive Manufacturing Consultant

Beyond purchase price, businesses must factor in:

- Facility requirements (power, ventilation, floor loading)

- Powder handling equipment ($30K-$150K)

- Post-processing solutions ($50K-$500K)

- Operator training ($5K-$25K per person)

- Software licenses ($5K-$30K annually)

The metal 3D printer cost calculation must include these factors for accurate budgeting and ROI projections.

From Prototypes to Production: Metal 3D Printing Trends Dominating 2025

Metal 3D printing has evolved dramatically from its prototype-focused origins. Five key trends have reshaped the landscape in 2025:

1. Scaled Production Economics

The cost-per-part curve has finally crossed traditional manufacturing methods for many components. Developments driving this include:

- Multi-laser systems operating simultaneously

- Automatic build chamber turnover reducing downtime

- AI-optimized build orientation and support strategies

Case Study: Siemens Energy Siemens Energy is now a leader in the production of gas turbine components, with 22,000 components annually, a volume that was impossible three years ago. Their use of metal additive manufacturing has helped reduce costs by 37% and improve dimensional accuracy and available performance metrics.

2. Material Library Expansion

The range of available metal 3D printing materials continues expanding beyond standard alloys:

- High-entropy alloys designed specifically for additive processes

- Gradient materials with programmed property transitions

- Ultra-high-temperature refractory metals for extreme applications

New aluminum alloys with crack-resistance properties have eliminated major barriers in aerospace applications, allowing for larger and more complex 3D printed metal parts than ever before.

3. Software-Driven Process Control

The intelligence layer has transformed reliability in metal 3D printers:

- Real-time melt pool monitoring with automated parameter adjustment

- Digital twins predicting part performance before printing starts

- Build simulations eliminating costly trial-and-error

One automotive supplier reduced development cycles by 71% through these advanced software implementations, demonstrating the power of digital tools in metal fabrication 3D printer workflows.

4. Supply Chain Integration

Metal 3D printing no longer operates in isolation:

- Distributed manufacturing networks balancing loads across facilities

- Blockchain verification ensuring part authenticity and specification compliance

- Just-in-time production eliminating warehouse costs

Jabil’s connected printer network exemplifies this approach, producing identical parts across three continents simultaneously an additive manufacturing solution that eliminates shipping delays and localization challenges.

5. Hybrid Manufacturing Systems

Combining additive and subtractive processes delivers the best of both worlds in advanced manufacturing technology:

- DMG MORI’s LASERTEC systems print and mill in single setups

- Automated pick-and-place robots transfer parts between processes

- Integrated inspection ensures quality throughout the workflow

READ MORE ABOUT: Additive Manufacturing in Aerospace: The Key Themes of 2025

How Metal 3D Printers Are Transforming Medical Implants in 2025

The marriage between medical needs and metal 3D printing technology has yielded remarkable advances in patient care and outcomes.

Patient-Specific Implants

Cookie-cutter solutions have given way to precision medicine. Surgeons now routinely order customized implants:

- Cranial reconstruction plates matching exact skull geometry

- Spinal fusion cages optimized for individual vertebral spacing

- Hip stems designed for specific bone density patterns

Case Study: Mayo Clinic Implementation A Mayo Clinic study found these customized solutions reduced surgical time by 36% and improved recovery metrics across all measured parameters. The metal 3D printing services they partnered with delivered implants within 72 hours of receiving patient scans – a timeline impossible with traditional manufacturing.

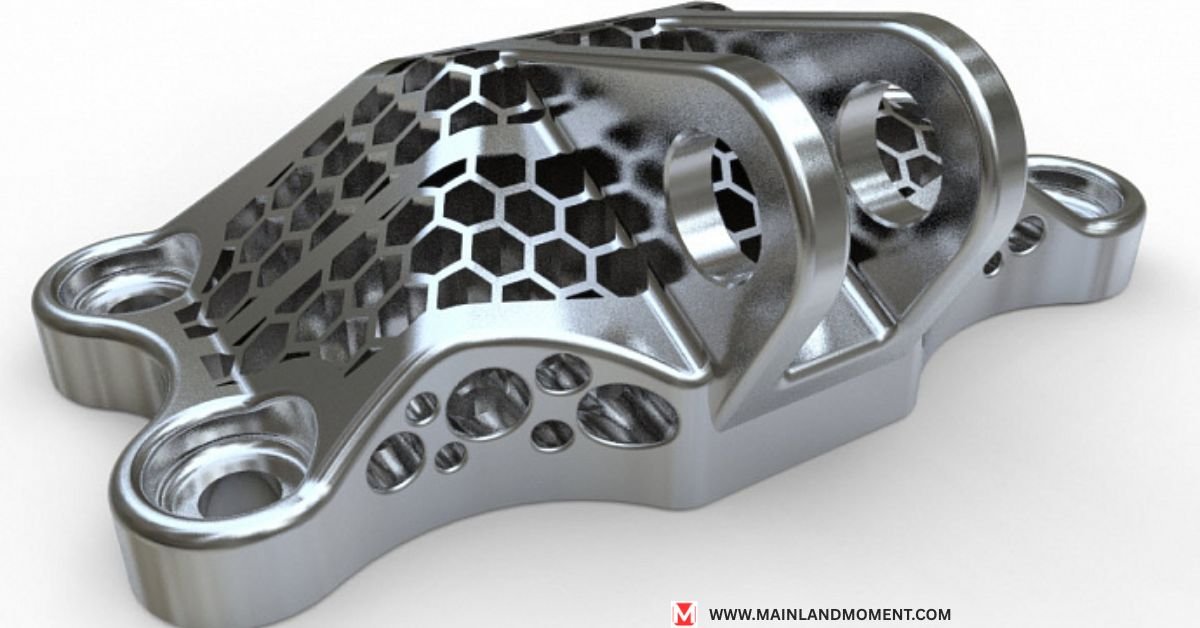

Lattice Structures for Osseointegration

Perhaps the most groundbreaking development involves designed porosity:

- Trabecular structures mimic natural bone architecture

- Surface roughness at the microscale promotes cell attachment

- Gradient porosity transitions support natural load distribution

These structures create the perfect environment for bone ingrowth. Recent five-year studies show 94% successful osseointegration compared to 78% with traditional implants – a dramatic improvement in outcomes enabled by precision 3D printing.

Sustainable Manufacturing: The Role of Metal 3D Printing in 2025's Green Revolution

Metal 3D printers deliver sustainability advantages that traditional manufacturing simply cannot match. As environmental concerns take center stage, these benefits have become increasingly valuable.

Material Efficiency Comparison:

| Manufacturing Method | Material Waste | Recyclability |

|---|---|---|

| Traditional Machining | 70-90% | Limited |

| Metal 3D Printing | 5-10% | Nearly Complete |

When working with precious or energy-intensive metals like titanium, this difference represents massive carbon footprint reductions. Unused powder in sustainable metal 3D printing gets recycled for future builds, creating near-zero-waste workflows.

Supply Chain Compression

Conventional manufacturing often involves multiple shipping stages:

- Raw materials shipping to foundries

- Castings shipping to machining facilities

- Components shipping to assembly plants

- Finished products shipping to distribution centers

Metal additive manufacturing condenses much of the processes and often limits the input shipments to just powder and finished products, which lowers transportation emissions substantially. As part of its Global Supply Chain initiative, GE Aviation was able to significantly improve its supply chain carbon footprint, reducing it by 43% through the use of strategic metal additive manufacturing.

The Lightweighting Advantage

Printed components are typically 30-50% lighter with equal performance specifications. In transport applications, the effects of reduced weight are multiplied over the lifetimes of product:

- A single 3D-printed aircraft bracket saving 100g translates to approximately 40kg of fuel saved annually per aircraft

- These savings multiply across thousands of components and hundreds of aircraft

Mastering Complex Designs: Why Metal 3D Printing Leads Innovation in 2025

Metal 3D printers have since opened design possibilities which were only theoretical several years ago. This design freedom enables new levels of innovation across sectors in several important ways:

Computational Design Tools

Traditional CAD has given way to advanced tools specifically for metal additive manufacturing:

- Generative design algorithms explore thousands of possibilities

- Topology optimization removes unnecessary material while maintaining strength

- Lattice structure wizards create custom internal geometries

Engineers at Relativity Space used these tools with their metal 3D printing technology to produce rocket components that consisted of 95% fewer parts than traditional variations – a drastic simplification enabled only through additive methodologies.

Cooling System Revolution

Thermal management has been transformed through high-precision metal printing:

- Conformal cooling channels that follow part contours exactly

- Variable diameter passages optimizing fluid dynamics

- Surface area maximization in minimal volumes

The future of metal 3D printing will be focused on making progress towards improving the value proposition between imagination and tangible reality for organizations. As the science of materials is perfected and the capabilities of machines improve, applications will continue to expand into new markets while achieving improving economics for more industries.

"What's revolutionary about metal 3D printing isn't just what we can make today – it's that we're finally free to design optimal solutions without the constraints that limited engineering for centuries." - David Park, Chief Engineer at InnovateX

David Park

Conclusion

The next phase of metal 3D printing should continue to erase the lines between imagination and reality. As the technology develops and materials science continues to mature, the applications will continue to expand into different territories while becoming more affordable for more industries.

For businesses which are contemplating implementation, at this point it is not about if there is value in metal 3D printing, but which applications hold the most ROI potential for their organization. It is important to understand both the capabilities and limitations of today’s technology to help assist businesses in understanding where to deploy and how to implement these revolutionary tools.

Pingback: Xbox One Controller In 2025: Is It Still Worth It For Gamers?